|

Radschool Association Magazine - Vol 35 Page 9 |

|

Privacy Policy | Editorial Policy | Join the Association | List of Members | Contact us | Index | Links | Print this page |

|

|

|

The Hotelicopter.

There’s an email doing the rounds which shows a giant helicopter that has supposedly been turned into an airborne hotel. As well as emails, several websites, including some that should know better, are reporting that a bloke named Alvin Farley has spent five years and tons of money, converting the world’s largest helicopter into the world’s first flying hotel.

The correspondence says that the hotelicopter is a modified Soviet Mil V-12 helicopter, is 137 feet long and features 16 cabins and two suites decked out with queen-size beds, heated toilets and spas.

Thing is,

the story has a few holes in it big enough to fly the Hotelicopter right

through.

The Mil V-12 is a real helicopter, but there’s no way Farley or anyone else bought one. The Soviets only ever built two. One remains at the facility where it was built and the other sits in a museum in Moscow.

It’s a good story, but unfortunately, it’s not true. Here’s the real story!!

In late March 2009, as a marketing stunt intended to promote the launch of their revamped and renamed hotel search engine web site, HOTELICOPTER.COM (previously known as VibeAgent) put up an April Fools page on the web announcing “the worlds first flying hotel”, with pictures and video advertising a Hotelicopter featuring “18 luxuriously-appointed rooms. Each soundproofed room is equipped with a queen-sized bed, fine linens, a mini-bar, coffee machine, wireless internet access, and all the luxurious appointments you'd expect from a flying five star hotel.

Room service is available one hour after lift off and prior to landing."

The interior shots of the Hotelicopter were lifted straight from Yotel, a chain of hotels that offers tiny room accommodation at European airports.

This April Fools prank was so good it continued to circulate and ensnare the unsuspecting long after April 1 had come and gone. To date it has received over 1.5 million page hits and still counting.

They even made a video of the Hotelicopter on its maiden flight and you can see that HERE.

Well done we say!!!

Global Warming.

The Arctic ocean is warming up, icebergs are growing scarcer and in some places the seals are finding the water too hot, according to a report to the US Commerce Dep't yesterday from Consulafft, at Bergen, Norway. Reports from fishermen, seal hunters, and explorers all point to a radical change in climate conditions and hitherto unheard-of temperatures in the Arctic zone. Exploration expeditions report that scarcely any ice has been met as far north as 81 degrees 29 minutes. Soundings to a depth of 3,100 meters showed the gulf stream still very warm. Great masses of ice have been replaced by moraines of earth and stones, the report continued, while at many points well known glaciers have entirely disappeared.

Very few seals and no white fish are found in the eastern Arctic, while vast shoals of herring and smelts which have never before ventured so far north, are being encountered in the old seal fishing grounds. Within a few years it is predicted that due to the ice melt the sea will rise and make most coastal cities uninhabitable.

(The above appeared in the Washington Post, November, 1922.)

|

|

Guns??

If you have ever wondered why America has never been invaded?,,,,,it will be easy to understand why after watching this video. Click HERE

|

|

I like telling self-deprecation jokes - but I'm not very good at it.

|

|

Un-Manned Air Vehicles. The Boeing A160 Hummingbird is an unmanned aerial vehicle (UAV) helicopter. Its design incorporates many new technologies never before used in helicopters, allowing for greater endurance and altitude than any helicopter currently in operation.

It looks like a normal helicopter but unlike any other helicopter on the market today, it can reach higher altitudes, hover for longer periods of time, go greater distances and operate much more quietly. And it features a unique optimum speed rotor technology that enables it to adjust the RPM of the rotor blades at different altitudes and cruise speeds.

The development of Hummingbird was begun by Frontier Systems Inc Aircraft back in 1998. Early A160s were powered by modified Subaru 4 cylinder boxer engines, but newer versions use Pratt & Whitney PW207D turboshaft engines. In May 2004, the company was acquired by Boeing and integrated into Boeing Phantom Works and then into the Advanced Systems group of Boeing Integrated Defense Systems. The aircraft's unique characteristics address current and emerging requirements of the U.S. armed forces, the U.S. Department of Homeland Security, and international military and security organizations.

A Boeing Phantom Works team, called Advanced Unmanned Systems-Concept Exploration, is developing the A160 under a contract with the Defense Advanced Research Projects Agency. The Hummingbird is designed to fly 2,500 nautical miles with endurance in excess of 24 hours and a payload of more than 300 pounds. Flights are largely autonomous, with the aircraft making its own decisions about how to fly itself so as to meet certain objectives, rather than relying on real-time human control. It is 35 feet long from nose to tail with a 36-foot rotor diameter. It will fly at an estimated top speed of 140 knots at ceilings up to 30,000 feet, which is about 10,000 feet higher than conventional helicopters can fly today. Future missions for the A160 include reconnaissance, surveillance, target acquisition, communications relay and precision re-supply.

The A160

flew for the first time in January 2002 at a former U.S. Air Force base

at Victorville, Calif., where flight-testing of the Hummingbird

continues. The A160's ability to stay aloft a long

Potential customers are also paying a lot of attention to the Hummingbird's unique optimal speed rotor system. During flight, an operator can vary the RPM of the A160's rotors (speed them up or slow them down) at different altitudes to improve overall efficiency and save fuel. This is quite a departure from conventional rotor systems, which tend to have a fixed rotor RPM regardless of altitude.

The Jeep. Someone sent us a video of about 6 soldiers who pull up on a main street in Halifax, Nova Scotia. They're in a standard issue WWII type Willys Jeep. In about 5 minutes, they completely disassemble the vehicle and reassemble it, then drive off in it fully operable! The idea is to show the genius that went into the making of the jeep and its basic simplicity. Click HERE (But - being a water cooled engine ???) |

|

|

|

I was walking down the street when I was accosted by a particularly dirty and shabby-looking homeless woman who asked me for a couple of dollars to buy some food. I took out my purse, got out ten dollars and asked, 'If I give you this money, will you buy wine with it instead of food? ''No”, she said, “I had to stop drinking years ago', the homeless woman told me. I said, 'Will you use it to go shopping instead of buying food?' She said. 'No, I don't waste time shopping, I need to spend all my time trying to stay alive. ''Will you spend this on a beauty salon instead of food?' I asked. 'Are you NUTS!' replied the homeless woman. I haven't had my hair done in 20 years!' 'Well, I said, 'I'm not going to give you the money. Instead, I'm going to take you out for dinner with my husband and me tonight. 'The homeless Woman was shocked . 'Won't your husband be furious with you for doing that? I know I'm dirty, and I probably smell pretty disgusting...'I said, 'That's okay. It's important for him to see what a woman looks like after she has given up shopping, hair appointments, and wine!!'

It’s a girl thing Rupe!!

|

|

Carp.

Asian carp were imported to North Americain in the 1970s to try and control algae growth in aquaculture and municipal wastewater treatment facilities however, as is usually the case, they escaped from captivity soon after their importation. As is the case in Australia, in the US they are considered a highly invasive species and efforts are being made to try and get rid of them. Carp together often reach extremely high population densities and have undesirable effects on the environment and on native species.

By 2003 carp had spread into the Mississippi, Illinois, Ohio, and Missouri rivers and many of their tributaries in the US. They are now (August 2009) abundant in the Mississippi River watershed from Louisiana to South Dakota and Illinois, and are close to invading the Great Lakes via the Chicago Sanitary and Ship Canal. Navigation dams on the Mississippi River seem to have slowed their advance up the Mississippi River and until late November 2008 carp had not been captured north of central Iowa on the Mississippi. Dams that do not have navigation locks are complete barriers to upstream natural movement of the carp, and it is important that fishermen do not assist this movement by the unintentional use of carp as bait.

The carp is also called the flying carp for its tendency to leap from the water when startled. They can grow to over 40 lb (18kg), and can leap 10 ft (3 m) in the air. Many boaters traveling in uncovered high-speed watercraft have been injured by running into the fish while at speed. In 2003 a woman jet-skiing broke her nose and a vertebra colliding with a carp and nearly drowned. In another example, a teenager's jaw was broken by a carp while being pulled on an inner tube. Water skiing in areas where carp are present is extremely dangerous.

Have a look at THIS.

|

|

An older man, not in the best physical condition, asked the Trainer in the gym, "I want to impress that beautiful girl over there. Which machine should I use?" The trainer replied, "Try the ATM outside the gym!"

|

|

The P76.

Mention really bad Australian cars and the name that usually springs to mind is the Leyland P76 though usually this sort of comment comes from people who have never owned one. I’ve had 3, (two were used as spares) – so I’m qualified to comment.

The P76 was not so much a bad car as a badly built car. This was Leyland Australia in its dying days with a dysfunctional management giving orders to get cars out the door whether they were finished or not. The missing bits could be added later. Introduced in 1973, it won a car-of-the-year award but was gone from the showrooms within two years.

The

design of the P76 had much to commend it.

The distinctive wedge-shaped body set it apart from its competitors, and

with the benefit of hindsight we can see that this revolutionary new

shape would become popular with other manufacturers in following years.

Instead of offering a vast range of body styles in line with its

competitors, Leyland decided that it would make only three, the

Executive, Super and Deluxe - all sedans!

The

wedge-shaped body was penned by Giovanni Michelotti and the V8 version

had the first all-alloy engine in an Australian-made car but it was

doomed because of trouble in the executive suite and on the shop floor.

Strikes

The P76 was probably the only car Leyland produced in either Australia or the UK which was directly badged “Leyland”, in contrast to “Leyland Mini” or “Leyland Marina”. Of course we all know it was the only one in which the parent company did not have any design/production involvement.

Launched in 1973, it was an attempt by BMC-Leyland to break into the lucrative Australian "Family Car" segment being held firmly by the 'Big Three', GM Holden with the Kingswood, Ford with the Falcon and Chrysler with the Valiant. Previously, BMC-Leyland had tried to compete in this market segment with the 1958 Morris Marshal (a rebadged Austin A95); the 1962 Austin Freeway and Wolseley 24/80. The Freeway was an Austin A60 with Riley 4/72 tail lights, a unique full width grille and a 2.4 litre 6-cylinder version of the 1622 cc B-series engine while the Wolseley was a 6-cylinder version of the Wolseley 16/60. They also had the 1971 Austin "X6" Tasman and Kimberley which were facelifted Austin 1800s with the 6-cylinder 2.2 litre E-series engine.

But in the changing times of the early '70's, most Australians wanted a large family sized car in their garage, and this was being reflected in declining sales of BMC's traditional products. Leyland set about developing a car specifically designed for the tough and harsh Aussie climate - and just as unforgiving roads!

For market acceptance, the P76 would have to follow the tradition of rear-wheel-drive with a 'big six' or V8 up front. But the Leyland engineers went much further than that, thinking outside the square and vastly improving on the family sedan formula. The shape was penned by Giovanni Michelotti and the entry-level P76 featured an enlarged 2623 cc version of the 6-cylinder engine from the smaller Austin Kimberley/Tasman. The top-of-the-line aluminium alloy 4416 cc V8 unit was unique to the P76, and was a derivative of the ex-Buick V8 that was powering the Rover 3500. The use of alloy in the V8's construction meant the difference in weight between the 6 and 8 was negligible.

The car was a full-size car in Australian terms, for which class leading boot capacity was claimed.

Leyland P76 with 44 gallon drum in the boot.

Safety equipment preceded the forthcoming Australian Design Rules and featured front discs as standard on all Models, recessed door handles and full-length side intrusion reinforcements on all doors. Transmissions for the car were bought from Borg-Warner Australia who were already supplying transmissions to Ford and Chrysler. Notwithstanding the advertising slogan ("Anything but average") the P76's engineering followed conventional lines.

It did offer a combination of features which were advanced in this category in Australia at the time: rack and pinion steering, power-assisted disc brakes, McPherson strut front suspension, front hinged bonnet, Glued in Windscreen and concealed windscreen wipers; as well as the familiar Australian made Borg Warner gearboxes (including a 3 speed column shift) and a live rear axle. Particular attention was paid to structural rigidity, a British Leyland engineering strength. This goal was aided by a conscious effort to reduce the number of panels needed to build the car's body — a remarkably low 215, reportedly only 5 more than for a Mini.

The P76 was potentially a superior car to its competitors and, had Leyland Australia been given time to develop the full P76 range, the model may well have succeeded in the Australian market. At the time P76 production ceased, Leyland was developing a V6 engine to replace the E6 variant. The V6 was derived from the 4.4-litre P76 V8, with the two rear cylinders chopped off.

The motoring press of the day were indeed very impressed with the advances made in the P76, and it should have come as no surprise that it would take out the coveted 1973 "Wheels Car of the Year" award. But the P76 was to have a dogged life - many pinning the eventual failure squarely at the marketing guys who, while correctly pointing out that its boot was big enough to hold a 44 gallon drum, left most Aussies scratching their heads and asking – why??

Even though the V8 model won Wheels magazine's Car of the Year for 1973, sales of the P76 were adversely affected by a variety of issues apart from the marketing issues, important component manufacturers' strikes limited parts availability, production problems at Leyland Australia's plant in Zetland restricted supply of the car and the release of the P76 coincided with the first Oil Crisis when fuel prices increased dramatically. As a result, demand for all larger cars subsided and sales did not reach expectations. British Leyland had intended to sell the P76 in the UK but production ceased before these plans could come to fruition.

When the car achieved success in the 1974 World Cup Rally - winning the Targa Florio trophy, Leyland Australia celebrated released a limited edition Targa Florio model: the V8 Super with sports wheels and steering wheel, as well as special paintwork, including side stripes.

The P76 Force 7

The

Force 7 coupé was announced in 1974 but never offered for sale. There

was to have been a base six-cylinder Force 7, a more powerful Force 7V

with the V8 unit and a range-topping Tour de Force. It was unusual in

that it had a large rear hatchback, the first of its kind produced in

Australia and shared only a few body panels with the sedan. At the time

of launch, the company announced the intention of introducing a station

wagon and at least two, maybe three, station wagons prototypes, which

shared much of the sedan's structure and body panels but with more

upright rear door frames, were built, one was crash tested by Ford

Australia for Leyland Australia, another was used as a factory hack and

one is in a private collection and currently undergoing restoration.

This ‘third’ one may, in fact, be the factory hack. This one was sold at

the same auction as the Force 7s and was sold as a part of a pair of

cars which included the last car made. These were thus obviously never

offered for commercial sale.

The Force 7 was one of the first hatchbacks to be released in Australia. There were to be three models of increasing price and luxury, from the base model equipped with a six cylinder engine and 3-speed column shift gearbox, followed by the awesome Force 7V fitted with a powerful 4.4 litre V8 'four-on-the-floor'. At the top of the tree was the "Tour de Force", featuring leather interior.

Despite promising reviews, the Force 7 range was ultimately doomed - it was simply too costly to manufacture! Other carmakers were borrowing heavily from their existing parts bin to create their hero cars; however the Force 7 range had only a handful of production elements in common with the P76 sedan - and so only around 60 Force 7's were manufactured with the majority being scrapped.

Only ten survived: one was sent to Leyland in the UK for testing and was subsequently bought by a British private collector; another is in the Birdwood Mill Museum in South Australia. The remaining eight were auctioned to the public when the line was discontinued in 1975 and they remain in private hands.

Ultimately, the P76 was a good car that suffered from a poor image. Perhaps the marketing team should have given the car a more significant name, so that it could effectively compete with the Kingswood, Falcon and Valiant. But more important in the public's perception of the car was the poor assembly quality, and problems with reliability and parts supply.

The Leyland showrooms became deserted - and BMC made the decision to cease production. But before they did, Leyland built approximately 300 limited-edition "Targa Florio", which featured auto transmissions, power steering and limited slip diffs - most were painted an eye-catching metallic navy blue with silver stripe detailing. Today the P76 has shaken its poor reputation to become very desirable and collectable - for they are at the very least a good talking point and represent a significant part of Australia's motoring history.

They were a great car, great to drive and I wish I still had mine!!!!

|

|

|

|

|

|

|

|

2011

This year we experienced and are going to experience four unusual dates: 1/1/11, 11/1/11, 1/11/11 and 11/11/11.

This is also the year of Money!!! This year October will have 5 Saturdays, 5 Sundays and 5 Mondays. This happens only every 823 years. These particular years are known as 'Moneybags.'

|

|

|

|

The VW.

Volkswagon, the company that made those funny little “go-anywhere”

beetle cars all those years ago has built an innovative production

facility in Germany where they build their luxury car – the Phaeton.

The Phaeton is a bit like a Passat on steroids and the idea behind it was to have a car that could compete with Mercedes and BMW. VW felt that since Benz had released the little A class car to compete against VW’s Golf that they would reciprocate.

It was also intended to support the Volkswagen brand image, since the most expensive versions of lesser models, such as the Golf GTI, were starting to cost almost as much as equivalently-sized prestige brands. Although the Volkswagen group already has a direct competitor in the full-sized luxury segment, the Audi A8, the Phaeton is intended to be more of a limousine like the Mercedes-Benz S-Class, while the A8 and BMW 7 Series are more sport-oriented.

The factory where these cars are made, is situated in the city center of

Dresden in Germany and is cert

The other 1200 parts and 34 preassembled components are shipped to a remote logistics center and are transferred from there to the factory via CarGoTrams that run on Dresden's public transport tracks.

You can see it HERE .

|

|

|

|

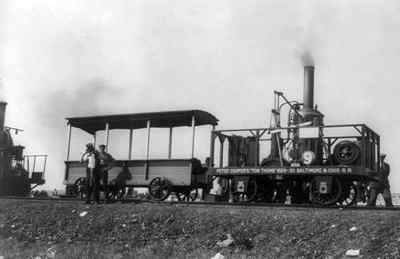

The Railroad.

Roads of rails called Wagonways were being used in Germany as early as 1550. These primitive railed roads consisted of wooden rails over which horse-drawn wagons or carts moved with greater ease than over dirt roads. Wagonways were the beginnings of modern railroads. By 1776, iron had replaced the wood in the rails and wheels on the carts. Wagonways evolved into Tramways and spread though out Europe. Horses still provided all the pulling power. In 1789, Englishman, William Jessup designed the first wagons with flanged wheels. The flange was a groove that allowed the wheels to better grip the rail, this was an important design that carried over to later locomotives.

The invention of the steam engine was critical to the invention of the modern railroad and trains. In 1803, a man named Samuel Homfray decided to fund the development of a steam-powered vehicle to replace the horse-drawn carts on the tramways and Richard Trevithick built the vehicle, the first steam engine tramway locomotive. On February 22, 1804, the locomotive hauled a load of 10 tons of iron, 70 men and five extra wagons the 9 miles between the ironworks at Pen-y-Darron in the town of Merthyr Tydfil, Wales to the bottom of the valley called Abercynnon. It took about two hours.

In 1821, Englishman, Julius Griffiths was the first person to patent a passenger road locomotive and in September, 1825, the Stockton & Darlington Railroad Company began as the first railroad to carry both goods and passengers on regular schedules using locomotives designed by English inventor, George Stephenson. Stephenson's locomotive pulled six loaded coal cars and 21 passenger cars with 450 passengers over 9 miles in about one hour.

George Stephenson is considered to be the inventor of the first steam locomotive engine for railways while Richard Trevithick's invention is considered the first tramway locomotive, however, his invention was really a road locomotive, designed for a road and not for a railroad.

Stephenson was extremely poor growing up and received little formal education. He worked in local collieries and was self-taught in reading and writing. In 1812, he became a colliery engine builder, and in 1814 he built his first locomotive for the Stockton and Darlington Railway Line. Stephenson was hired as the company engineer and soon convinced the owners to use steam motive power and built the line's first locomotive, the Locomotion. In 1825, Stephenson moved to the Liverpool and Manchester Railway, where together with his son Robert built the Rocket. (right)

John Stevens is considered to be the father of American railroads. In 1826 he demonstrated the feasibility of steam locomotion on a circular experimental track constructed on his estate in Hoboken, New Jersey, three years before George Stephenson perfected a practical steam locomotive in England.

The

first railroad charter in North America was granted to John Stevens in

1815. Grants to others followed, and work soon began on the first

operational railroads. Designed and built by Peter Cooper in 1830, the

Tom Thumb was the first American-built steam locomotive to be operated

on a common-carrier railroad. The Baltimore & Ohio Railroad became the

first U.S. railway chartered for commercial transport of passengers and

freight. There were sceptics who d

The first railroad track in the United States was only 13 miles long, but it caused a lot of excitement when it opened in 1830. Charles Carroll, the last surviving signer of the Declaration of Independence, laid the first stone when construction on the track began at Baltimore harbour on July 4, 1828.

Back then, the laying of track was a backbreaking job, all done by hand. Have a look at how it’s done today, what an amazing piece of machinery – click HERE

Bikini Wax.

Makes your eyes water just thinking about it, check THIS.

|

|

|

|

|

|

|

|

Back Go to page: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Forward

|

time at high

altitudes is drawing considerable interest from the U.S. Army, the U.S.

Navy and U.S. Special Operations Forces.

time at high

altitudes is drawing considerable interest from the U.S. Army, the U.S.

Navy and U.S. Special Operations Forces.

.jpg)

.jpg) disrupted the supply of parts and incomplete cars rolled off the

production line to be cobbled together later in the yard. Not only was

the finish quality poor but a series of mechanical problems, such as an

oil-guzzling V8, gave the car a reputation for unreliability. Even Gough Whitlam called the P76 a dud, though that’s a bit like the pot calling

the kettle………

disrupted the supply of parts and incomplete cars rolled off the

production line to be cobbled together later in the yard. Not only was

the finish quality poor but a series of mechanical problems, such as an

oil-guzzling V8, gave the car a reputation for unreliability. Even Gough Whitlam called the P76 a dud, though that’s a bit like the pot calling

the kettle……….jpg)